The modern world is highly creative and ambitious, packed full of incredible designs and designers who are always looking to create something unique and beautiful. Recently, more and more of these talented designers are turning to high pressure laminates (HPL) to help turn their vision into a reality.The modern world is highly creative and ambitious, packed full of incredible designs and designers who are always looking to create something unique and beautiful. Recently, more and more of these talented designers are turning to high pressure laminates (HPL) to help turn their vision into a reality.

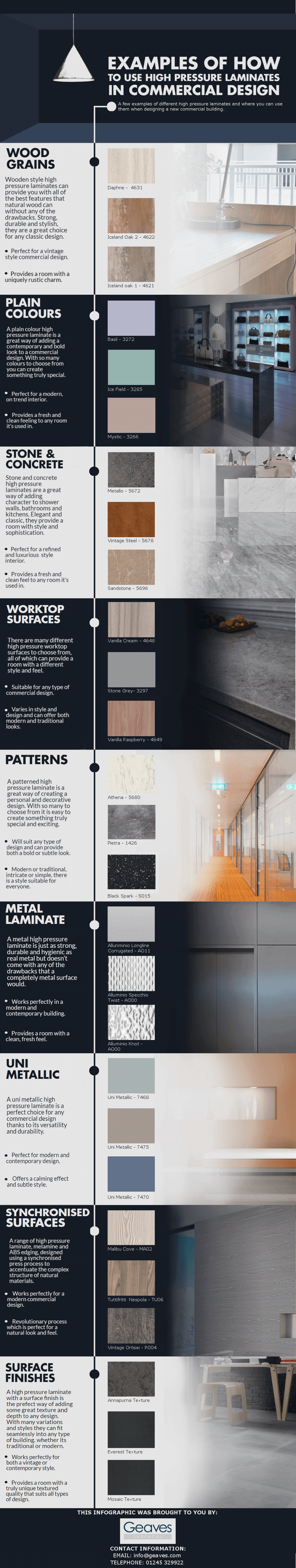

High pressure laminates have so many different styles and finishes that it’s no surprise to see why so many people are using it in commercial design. Whether they are creating a new high-end clothing store or a new London restaurant, HPL will be able to suit these designs thanks to its versatility and endless potential.

That being said, it’s not only commercial designers who are using it. Many people who are redesigning their kitchen or bathroom are using high pressure laminates to achieve a smooth, stylish and hygienic finish. It has many different abilities, which are:

- Hygienic – A high pressure laminate surface is extremely hygienic, so much so that it can be found in hospitals, schools and dentists.

- Robust – Thanks to its manufacturing process it is one of the strongest surfaces around. Strong yet stylish, HPL is incredibly robust and resilient.

- Dependable – Frequently used in places where there is a high risk of damage, such as schools or bars, thanks to its antibacterial, anti-fungi, water and heat resistant qualities it won’t let you down.

- Consistent – Due to its reliable consistency many companies look to it when franchising a restaurant or bar as they are able to easily keep the same style throughout their locations.

- Stylish – Extremely stylish due to its vast array of patterns, designs, colours and textures. Perfectly able to balance style with function, high pressure laminate can be used in both bright, bold designs and smooth, subtle designs.

- Versatile – Possibly its best feature is just how versatile it is. It will perfectly suit any type of style, from contemporary elegance to rustic charm and everything in-between.

The manufacturing of HPL is a complex and precise process. Firstly, the paper that is being used is impregnated with the resins, then three layers of paper/resin are placed into a press which simultaneously applies heat and pressure. This operation allows the thermoset resins to flow into the paper, then subsequently cure into a consolidated sheet with a density greater than 1,35 g/cm³. The surface finish that gives the high pressure laminate its unique style occurs during the press cycle as it can be cured while in contact with a textured surface. It consists of 60 to 70% paper and 30 to 40% a combination of phenol-formaldehyde resin for the core layers and melamine-formaldehyde resin for the surface layer.

Now that you know a little more about this great surface solution why not find out how this can help you with your designs. To find out which high pressure laminates suit which style please check out the infographic below.

Infographic Source: http://geaves.com/why-high-pressure-laminates-are-being-used-more-and-more-in-commercial-design/

Infographic Portal New Infographics Resource Portal

Infographic Portal New Infographics Resource Portal