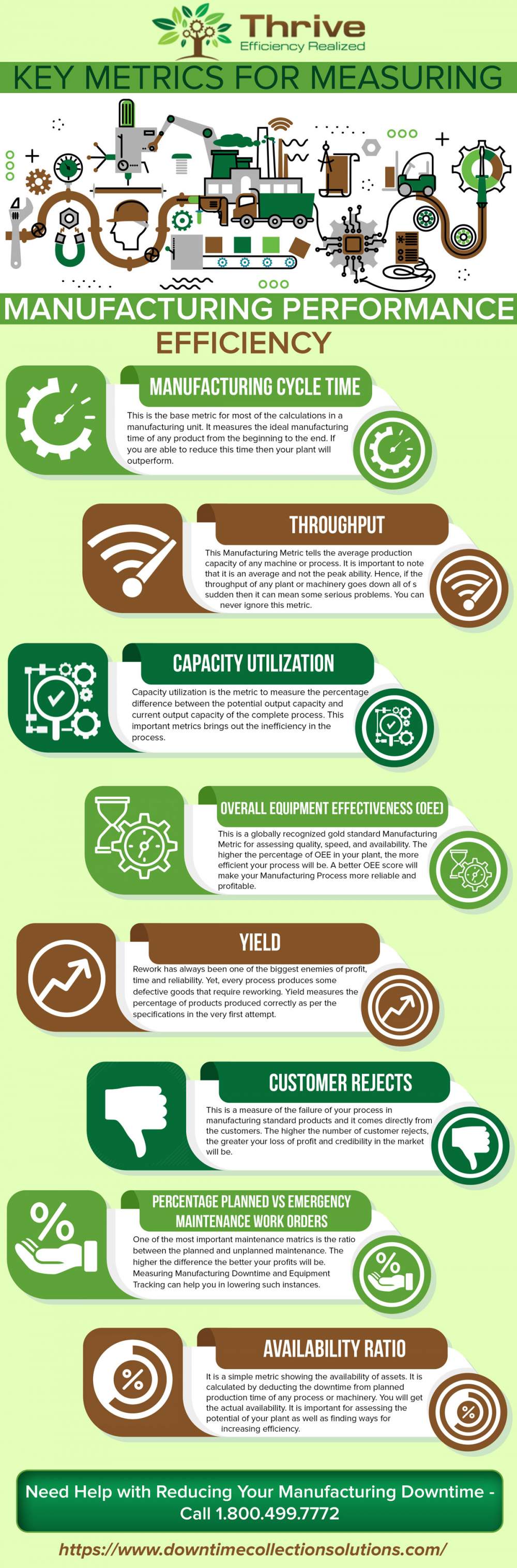

Manufacturing Cycle Time: This is the base metric of the calculations in a manufacturing unit. It measures the ideal manufacturing time of any product from the beginning to the end. If you are able to reduce this time then your plant will outperform.

Throughput: This manufacturing metric tells the average production capacity of any machine or process. It is important to note that it is an average and not the peak ability. Hence if the throughput of any plant or machinery goes down all of sudden then it can mean some serious problems. You can never ignore this metric.

Capacity Utilization: Capacity utilization is the metric to measure the percentage difference between the potential output capacity and current output capacity of the complete process. This important metrics begins out the inefficiency in the process.

Overall Equipment effectiveness (OEE): This is globally recognized gold standard manufacturing metric for assessing quality, speed, and availability. The higher the percentage of OEE in your plant, the more efficient your process will be. A better OEE score will make your manufacturing process more reliable and profitable.

Yield: Rework has always been one of the biggest elements of enemies of profit, time and reliability. Yet, every process produces some defective goods that require reworking. Yield measures the percentage of products produced correctly as per the specifications in the very first attempt.

Customer Rejects: This is measure of failure of your process in manufacturing standard products and it comes directly from the customers. The higher the number of customer rejects, the greater your loss of profit and credibility in the market will be.

Percentage Planned VS Emergency Maintenance Work Orders: One of the most important maintenance metrics in the ratio between the planned and unplanned maintenance. The higher the difference the better your profits will be. Measuring manufacturing Downtime and Equipment Tracking can help you in lowering such instances.

Availability Ratio: It is simple metric showing the availability of assets. It is calculated by deducting the downtime from planned production time of any process or machinery. You will get the actual availability. It is important for assessing the potential of your plant as well as finding ways for increasing efficiency.

Infographic Source: https://www.downtimecollectionsolutions.com/key-metrics-for-measuring-manufacturing-performance/

Tags Efficiency Key Matrices Manufacturing Measuring Performance

Check Also

Must Use Ai Tools In 2024

As we venture further into 2024, the importance of leveraging AI tools to enhance productivity, …

Infographic Portal New Infographics Resource Portal

Infographic Portal New Infographics Resource Portal